Carel’s humidification. Humidity is simply the presence of water vapour in the air.Relative humidity is the quantity of moisture present in the air at a certain temperature (e.g., 50% rH at 20 °C) as a proportion of the maximum quantity of water vapour that the air can hold at that temperature when it is saturated (100% rH at 20 °C).

Catalogs

Instructions

Selection software

humiDisk can be used both with demineralized water and mains water.

humiSonic range comprises two versions, meeting the needs of all applications: humiSonic compact, small enough to be installed on a fan coil, and humiSonic direct, for room distribution. Ultrasonic humidifiers feature a small water storage tank and piezoelectric transducers installed at the bottom of the tank. The surface of the transducer vibrates at very high speed (1.65 million times a second), a speed that does not allow the water to move due to its inertial mass. During the negative amplitude of the transducer cycle, a sudden void is created that brings about the production of microscopic bubbles, which are pushed to the surface of the water during the positive amplitude of the cycle. This effect is called cavitation.

During this process, the resulting intersecting sound waves created directly underneath the surface of the water cause very small droplets of water to separate, forming a fine mist of vapour that is immediately absorbed by the flow of air.

Compressed air humidifiers are the ideal humidification solution whenever a compressed air supply is available, as is the case in many industrial applications, even if humidification systems are often fitted with a dedicated air compressor. The humidifier essentially consists of a cabinet fitted with electronic controller that, using two independent connection pipe networks, supplies the spray nozzles with compressed air and water at the ideal pressure for instant operating conditions. The units can be installed inside an AHU or directly in the room where humidity needs to be controlled. The greatest advantage of these atomisers is the minute dimensions of the droplets produced and their thorough mixing in the compressed air that, due to its speed, distributes the aerosol in the room and consequently allows quick absorption. These units can therefore be readily used for direct cooling in rooms, and are ideal for the textile industry, wood and paper processing, and storerooms, where there is almost always a supply of compressed air.

mc multizone features an electronic controller that manages the supply of water and compressed air to the nozzles.

Water atomisation is managed by an external control signal or, in the case of stand-alone control, so as to maintain the humidity/temperature set point. The unit also manages a series of automatic cycles, such as nozzle cleaning and washing.

The system has the ability to control humidity independently in multiple zones (rooms, AHUs, cold rooms) using a masterslave layout. The layout has one master and multiple slaves (up to 5) connected in a pLAN. The master is fitted with a display for accessing the readings, viewing the status and messages on the master and slaves. The slaves have their own internal controller and can be set to continue operating even if connection to the master is interrupted.

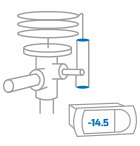

Pressurised water humidifiers exploit the potential energy transferred to the water by a special volumetric pump in the form of high pressure (generally 70 bars), so as to achieve very fine atomisation through special nozzles.

The most common application of these humidifiers is in AHUs, where the pressurised water distribution system is installed. In industrial environments for processing wood or paper, or in the textiles industry, systems are often used to distribute atomised water directly into the rooms. As well as humidity control, pressurised water atomisers are the best solution for fully exploiting the potential offeredby evaporative cooling, both direct and indirect, inside AHUs or in rooms, as in the case of industrial facilities and large public spaces, such as metropolitan railway stations and airports.

One crucial aspect is the hygiene that pressurised water humidifiers must guarantee in the application where they are used. Management of washing cycles, the materials used and the configuration of the atomised water distribution system are the main features that guarantee CAREL humidifiers comply with the strictest hygiene regulations in force (VDI6022). humiFog multizone represents the new generation in high pressure atomised water humidifiers.

A volumetric pump sends water at high pressure to a distribution system made up of nozzles that atomise the water into very fine droplets, which can be absorbed by the air in a very short space.

"Evaporative Cooling" is the process in which water cools the air through evaporation. For this to happen spontaneously, without the contribution of external energy, the water must be atomised in the air as very fine water droplets which, having a lower surface tension than the surrounding air, evaporate into the air.